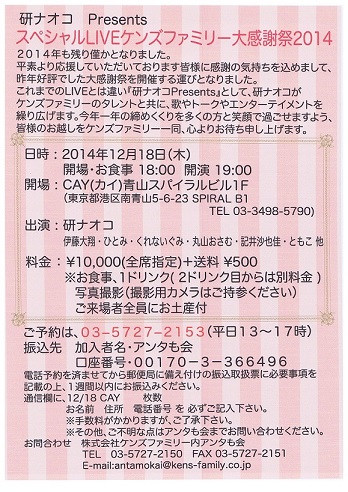

研ナオコ Presents スペシャルLIVE ケンズファミリー大感謝祭2014

2014年11月30日

【研ナオコ Presents スペシャルLIVE ケンズファミリー大感謝祭 2014】

研ナオコ・伊藤大翔・ひとみ・くれないぐみ・ 丸山おさむ・記井沙也佳・ともこ 他出演!

チケットは弊社でも販売中です!!

お気軽にお問い合わせください

この記事へのコメント

(Mikayla)

Cucumber ribbon, cherry tomato, feta cheese, pickled red onion, mesclun lettuce, ranch dressing Our facilities are world-class, as is our catering and breathtaking beachfront

location…no wonder our venues are popular with function and event organisers

worldwide. Mindil Beach Casino Resort is the premium business and events

destination in the Top End and features Darwin’s only

five-star resort and four-star hotel. Relax and

enjoy appetizers that are perfect for sharing, award-winning cocktails (or maybe a top-shelf whisky), and listen to live tunes from NT’s

most talented musicians. Sandbar?is the place

to be for after-work drinks or simple, relaxed dining with friends.

Best enjoyed with friends, our banquet menu options are an easy crowd-pleaser

featuring a wide variety of our most popular dishes.

Join us on the lawns on Saturday, 26th April 2025 from 5pm for fun, food

and entertainment in true territory style.

But there’s still a chance to join the celebration ? limited table bookings

are still available at Sandbar and il Piatto, offering prime positioning and

a premium experience. All Gaming & Major Promotions are R18 & exclusive to Lucky

North Club Members. This Dry Season, experience the enchantment and energy of Carnivale brought

to life in a way only Mindil Beach Casino Resort

can deliver. From 19 July, earn entries and join us every hour from 6pm on Saturdays & 3pm on Sundays for your shot at another game

show-style excitement!

If you love the whole cocktail-sipping, sun-soaking beach club experience, INFINITY

at the Mindil Beach Casino Resort is the ultimate venue where Darwin’s

social scene hits a whole new level. Situated on the

resort's expansive lagoon, these rooms offer swim out access, private sun lounges plus an outdoor setting

on your private balcony. The spacious one bedroom suites offer guests an elegantly appointed lounge area, a marble ensuite and luxurious corner spa,

and a private balcony with views of the lush tropical gardens,

pool or ocean. The elegantly appointed lounge features separate living and dining areas which can host up to six people and has two

private balconies.Bedrooms offer guests a sanctuary with a marble ensuite and a balcony with magnificent views.

Grand suites offer guests the space to relax and enjoy the natural beauty of lush tropical gardens.

location…no wonder our venues are popular with function and event organisers

worldwide. Mindil Beach Casino Resort is the premium business and events

destination in the Top End and features Darwin’s only

five-star resort and four-star hotel. Relax and

enjoy appetizers that are perfect for sharing, award-winning cocktails (or maybe a top-shelf whisky), and listen to live tunes from NT’s

most talented musicians. Sandbar?is the place

to be for after-work drinks or simple, relaxed dining with friends.

Best enjoyed with friends, our banquet menu options are an easy crowd-pleaser

featuring a wide variety of our most popular dishes.

Join us on the lawns on Saturday, 26th April 2025 from 5pm for fun, food

and entertainment in true territory style.

But there’s still a chance to join the celebration ? limited table bookings

are still available at Sandbar and il Piatto, offering prime positioning and

a premium experience. All Gaming & Major Promotions are R18 & exclusive to Lucky

North Club Members. This Dry Season, experience the enchantment and energy of Carnivale brought

to life in a way only Mindil Beach Casino Resort

can deliver. From 19 July, earn entries and join us every hour from 6pm on Saturdays & 3pm on Sundays for your shot at another game

show-style excitement!

If you love the whole cocktail-sipping, sun-soaking beach club experience, INFINITY

at the Mindil Beach Casino Resort is the ultimate venue where Darwin’s

social scene hits a whole new level. Situated on the

resort's expansive lagoon, these rooms offer swim out access, private sun lounges plus an outdoor setting

on your private balcony. The spacious one bedroom suites offer guests an elegantly appointed lounge area, a marble ensuite and luxurious corner spa,

and a private balcony with views of the lush tropical gardens,

pool or ocean. The elegantly appointed lounge features separate living and dining areas which can host up to six people and has two

private balconies.Bedrooms offer guests a sanctuary with a marble ensuite and a balcony with magnificent views.

Grand suites offer guests the space to relax and enjoy the natural beauty of lush tropical gardens.

[2025-12-31 18:03:26.740283]

URL

(Gregory)

In the table you list for the blue USB port "Twice as fast as the Blue USB Port." That’s a little error there.

I bet the majority of people don’t even realize there are different colors and that

the different colors have different meanings and applications, LOL.

I thank you for sharing your knowledge on these cables/ports.

It should say "It’s much faster than the WHITE port" not black.

Once you've signed in, check your email by opening your inbox.

We work hard to protect you from spam, phishing, and malware, before they

reach your inbox. Google Workspace is a set of productivity and

collaboration tools that helps individuals, teams, and businesses stay on top

of everything. Gmail offline lets you read, reply, delete,

and search your Gmail messages when you’re not connected to the

internet.

Can u detail what voltage range it support from standard 5V and difference between q and PD for type A

which seem to be non standard

I bet the majority of people don’t even realize there are different colors and that

the different colors have different meanings and applications, LOL.

I thank you for sharing your knowledge on these cables/ports.

It should say "It’s much faster than the WHITE port" not black.

Once you've signed in, check your email by opening your inbox.

We work hard to protect you from spam, phishing, and malware, before they

reach your inbox. Google Workspace is a set of productivity and

collaboration tools that helps individuals, teams, and businesses stay on top

of everything. Gmail offline lets you read, reply, delete,

and search your Gmail messages when you’re not connected to the

internet.

Can u detail what voltage range it support from standard 5V and difference between q and PD for type A

which seem to be non standard

[2025-12-28 00:32:41.535835]

URL

(Bud)

Right across the bridge in Oakland, you can find the?Oaks Card Club, while the best casinos in San Jose include?Pharaoh’s Palace and Garden City.

Other gambling locations in the city include the?Trump Plaza, Showboat, Taj Mahal, Harrah’s and Trump Marina.

The three most popular casinos sitting right on the

beach are Tropicana, Sands, and Caesars. The biggest city known for gambling after Las Vegas

is Atlantic City that belongs to the?state of New Jersey.

In the part of town called Sparks, you can find great casinos like?John Ascuaga’s Nugget, Silver

Club, Dotty’s and Mint Casino.

Casino du Lac-Leamy has 1,400+ slots and 60 gable games to choose from.

But it’s still a great choice if you’re looking for a high-quality gaming experience.

You’ll also find Mise-o-jeu+ sports betting terminals to be on your favourite teams.

Other gambling locations in the city include the?Trump Plaza, Showboat, Taj Mahal, Harrah’s and Trump Marina.

The three most popular casinos sitting right on the

beach are Tropicana, Sands, and Caesars. The biggest city known for gambling after Las Vegas

is Atlantic City that belongs to the?state of New Jersey.

In the part of town called Sparks, you can find great casinos like?John Ascuaga’s Nugget, Silver

Club, Dotty’s and Mint Casino.

Casino du Lac-Leamy has 1,400+ slots and 60 gable games to choose from.

But it’s still a great choice if you’re looking for a high-quality gaming experience.

You’ll also find Mise-o-jeu+ sports betting terminals to be on your favourite teams.

[2025-12-27 23:02:08.749457]

URL

(Blanca)

Reputable casinos use military-grade encryption to safeguard your personal and financial information. That’s why they’re called "offshore casinos." These are typically

licensed by Curaçao, Anjouan, Malta, or Kahnawake rather than Australian authorities.

Most accessible casinos hold licences from jurisdictions like Malta, Curaçao or Kahnawake.

You can take your pick from various games and see which ones you enjoy the most.

In order to satisfy those 30x wagering requirements, though,

you have to wager the combined amount of your deposit

and bonus 30 times over. If you’re having a bad streak of luck,

cashback offers return a percentage of your losses in the form of?a

bonus credit.

If baccarat is your game, don’t miss this thorough baccarat strategy guide to gain an edge.

It’s up to you to decide what they are and find the casino that matches them.

The truth is that the casino you find the best

will depend on a variety of factors that are unique to you!

licensed by Curaçao, Anjouan, Malta, or Kahnawake rather than Australian authorities.

Most accessible casinos hold licences from jurisdictions like Malta, Curaçao or Kahnawake.

You can take your pick from various games and see which ones you enjoy the most.

In order to satisfy those 30x wagering requirements, though,

you have to wager the combined amount of your deposit

and bonus 30 times over. If you’re having a bad streak of luck,

cashback offers return a percentage of your losses in the form of?a

bonus credit.

If baccarat is your game, don’t miss this thorough baccarat strategy guide to gain an edge.

It’s up to you to decide what they are and find the casino that matches them.

The truth is that the casino you find the best

will depend on a variety of factors that are unique to you!

[2025-12-27 10:41:29.58267]

URL

(Mervin)

Choose between an AI-powered instant machine or perfect translation by a linguist with quick delivery, ensuring error-free localization of your JSON.

Perfect for refining post-AI and machine-generated content to ensure natural, flawless

text. The English dictionary includes the Cambridge Advanced Learner’s Dictionary, the Cambridge Academic Content Dictionary, and the

Cambridge Business English Dictionary. Choose from corpus-informed dictionaries for English language

learners at all levels. Perfect your business writing, with style

and tone adaptations to fit your brand and target audience.

It doesn’t offer the highest quality, but it is a free online

translator. Machine language processing doesn’t focus

on nuances such as context or tone of voice. Trusted by global companies

worldwide, Translate.com provides quality end-to-end website

localization solutions that your business can depend on for years.

We’ve been building industry-leading technology for years to ensure your website is translated quickly.

We translate PDFs into English, German, French,

Spanish, and Japanese. Leverage the power of AI and human translator team in one tool.

The train from Sydney to Canberra will take approximately 4 hours.

Explore the most current information on trains from Sydney to Canberra

Sydney Airport?International Terminal T1,Bay 9,

bus & coach bays This service stops daily at the

Sydney International Airport (T1). Please check our booking page for service availability.

Perfect for refining post-AI and machine-generated content to ensure natural, flawless

text. The English dictionary includes the Cambridge Advanced Learner’s Dictionary, the Cambridge Academic Content Dictionary, and the

Cambridge Business English Dictionary. Choose from corpus-informed dictionaries for English language

learners at all levels. Perfect your business writing, with style

and tone adaptations to fit your brand and target audience.

It doesn’t offer the highest quality, but it is a free online

translator. Machine language processing doesn’t focus

on nuances such as context or tone of voice. Trusted by global companies

worldwide, Translate.com provides quality end-to-end website

localization solutions that your business can depend on for years.

We’ve been building industry-leading technology for years to ensure your website is translated quickly.

We translate PDFs into English, German, French,

Spanish, and Japanese. Leverage the power of AI and human translator team in one tool.

The train from Sydney to Canberra will take approximately 4 hours.

Explore the most current information on trains from Sydney to Canberra

Sydney Airport?International Terminal T1,Bay 9,

bus & coach bays This service stops daily at the

Sydney International Airport (T1). Please check our booking page for service availability.

[2025-12-27 09:45:08.557817]

URL

(Yasmin)

Diese Spiele machen viel Spaß und sind eine der neuesten Entwicklungen in der Welt der Automatenspiele.

Es gibt auch Jackpot-Spiele, bei denen die Einsätze aller

Spieler der besten online Casinos in den Jackpot einfließen, wodurch

noch größere Summen im Jackpot landen. Außerdem

gibt es bei Lucky7Even DE viele Arten von online Casino Echtgeld

Spielautomaten mit unterschiedlichen Themen und Designs. Du kannst dabei aus einer Vielzahl von Themen und Spielarten wählen, darunter Video-Slots, progressive Jackpot-Slots,

online Blackjack, online Roulette, Baccarat und mehr.

Ob Tischspiele, Live-Games, die beliebtesten Slots und vieles mehr.

Casinolucky7even.com ist eine Online-Ressource, die sich mit dem

beliebten Casino Lucky7even befasst. Glücksspiele sollten unterhaltsam sein und

verantwortungsvoll betrieben werden. Der Willkommensbonus war großartig, und die laufenden Promotionen halten die Dinge spannend.

Virtuelle Versionen von Spielen wie Roulette, Blackjack und Baccarat finden Sie unter Tischspiele, die

Sie nach Namen durchsuchen können. Der Wettbereich bietet eine Vielzahl von Disziplinen mit Optionen für Linien- und Livewetten. Lucky7even bietet eine Demoversion der Spielautomaten an, die für alle

Benutzer zugänglich ist und keine Anmeldung

erfordert.

Es gibt auch Jackpot-Spiele, bei denen die Einsätze aller

Spieler der besten online Casinos in den Jackpot einfließen, wodurch

noch größere Summen im Jackpot landen. Außerdem

gibt es bei Lucky7Even DE viele Arten von online Casino Echtgeld

Spielautomaten mit unterschiedlichen Themen und Designs. Du kannst dabei aus einer Vielzahl von Themen und Spielarten wählen, darunter Video-Slots, progressive Jackpot-Slots,

online Blackjack, online Roulette, Baccarat und mehr.

Ob Tischspiele, Live-Games, die beliebtesten Slots und vieles mehr.

Casinolucky7even.com ist eine Online-Ressource, die sich mit dem

beliebten Casino Lucky7even befasst. Glücksspiele sollten unterhaltsam sein und

verantwortungsvoll betrieben werden. Der Willkommensbonus war großartig, und die laufenden Promotionen halten die Dinge spannend.

Virtuelle Versionen von Spielen wie Roulette, Blackjack und Baccarat finden Sie unter Tischspiele, die

Sie nach Namen durchsuchen können. Der Wettbereich bietet eine Vielzahl von Disziplinen mit Optionen für Linien- und Livewetten. Lucky7even bietet eine Demoversion der Spielautomaten an, die für alle

Benutzer zugänglich ist und keine Anmeldung

erfordert.

[2025-12-21 15:14:51.424363]

URL

(Levi)

Keine Notwendigkeit, sich um Einzahlungen oder Abhebungen online

zu kümmern - wir halten es hier in unserem physischen Casino einfach und altmodisch.

Egal, ob Sie ein erfahrener Profi sind oder gerade erst anfangen,

die Spielbank Bad Neuenahr hat für jeden etwas

zu bieten. Darüber hinaus sorgen sofortige Barauszahlungen und ein engagiertes Support-Team, das jederzeit zur Verfügung steht, dafür, dass Ihr Spielerlebnis neue

Höhen erreicht. Mit über 80 Spielautomaten, darunter beliebte Titel wie Dragon Link, Lightning Link und Mo' Mummy JP, haben Sie die Qual der

Wahl. Als geschätzter Spieler genießen Sie Cashback-Belohnungen durch unser VIP-Programm und exklusiven Zugang zu saisonalen Turnieren.

Genießt barrierefreien Zugang, klimatisierten Komfort

und automatisierte Jackpots, die darauf warten, gewonnen zu werden - besucht uns noch heute und entdeckt euer neues Lieblingsziel!

Das Engagement der Spielbank für die Einhaltung und Aufsicht fördert das Vertrauen der Gäste und macht sie zu

einem attraktiven Ziel für diejenigen, die ein erstklassiges Spielerlebnis in Deutschland

suchen. Als voll lizenziertes Unternehmen hält es sich an die deutschen Glücksspielvorschriften und bietet eine sichere Umgebung für jeden Spieler.

Unser freundliches Personal wird Sie durch den Prozess führen und Ihnen helfen, sich

für ein großartiges Spielerlebnis einzurichten. In der Spielbank Bad Neuenahr Online werden neue Besucher mit einem exklusiven Willkommens-Erlebnis

empfangen, das den Ton für ein luxuriöses Spielerlebnis angibt.

zu kümmern - wir halten es hier in unserem physischen Casino einfach und altmodisch.

Egal, ob Sie ein erfahrener Profi sind oder gerade erst anfangen,

die Spielbank Bad Neuenahr hat für jeden etwas

zu bieten. Darüber hinaus sorgen sofortige Barauszahlungen und ein engagiertes Support-Team, das jederzeit zur Verfügung steht, dafür, dass Ihr Spielerlebnis neue

Höhen erreicht. Mit über 80 Spielautomaten, darunter beliebte Titel wie Dragon Link, Lightning Link und Mo' Mummy JP, haben Sie die Qual der

Wahl. Als geschätzter Spieler genießen Sie Cashback-Belohnungen durch unser VIP-Programm und exklusiven Zugang zu saisonalen Turnieren.

Genießt barrierefreien Zugang, klimatisierten Komfort

und automatisierte Jackpots, die darauf warten, gewonnen zu werden - besucht uns noch heute und entdeckt euer neues Lieblingsziel!

Das Engagement der Spielbank für die Einhaltung und Aufsicht fördert das Vertrauen der Gäste und macht sie zu

einem attraktiven Ziel für diejenigen, die ein erstklassiges Spielerlebnis in Deutschland

suchen. Als voll lizenziertes Unternehmen hält es sich an die deutschen Glücksspielvorschriften und bietet eine sichere Umgebung für jeden Spieler.

Unser freundliches Personal wird Sie durch den Prozess führen und Ihnen helfen, sich

für ein großartiges Spielerlebnis einzurichten. In der Spielbank Bad Neuenahr Online werden neue Besucher mit einem exklusiven Willkommens-Erlebnis

empfangen, das den Ton für ein luxuriöses Spielerlebnis angibt.

[2025-12-21 03:50:06.481384]

URL

(Christy)

Für die Registrierung im Platin Casino sind 20 Freispiele ohne Einzahlung ausgelobt.

Gemeint ist hier ein Freispiele Bonus ohne Einzahlung,

also die belohnte Registrierung. Kostenlose Online Casino Freispiele sind tatsächlich ohne Kosten möglich.

Um Freispiele in einem Casino im Internet zugeteilt zu bekommen, muss

man sich zuvor registrieren. Online Casino Freispiele oder anders ausgedrückt Free Spins, sind

in den besten Online Casinos ein Standard. Es ist daher absolut zu empfehlen, schon vor der Aktivierung der Freispiele einen genauen Blick auf

die Bedingungen und AGB des Casinos zu werfen. Die Merkur

Magie Automatenspiele können bei den meisten Anbietern auch mit Mobilgeräten gespielt werden.

Sie spielen stets direkt in dem Browser Ihrer Wahl und genießen dabei beste

graphische Auflösung. Erfahren Sie, wie Scatter-Symbole und weitere Besonderheiten funktionieren, und testen Sie, auf welchen Einsatzstufen Sie

das Spiel spielen wollen oder ob Sie die Gewinnlinien ändern können. Der Vorteil im Online Casino

ist, dass bei Online Slots und an den virtuellen Spieltischen die Limits sehr niedrig

sind, sodass Sie schon um geringe Summen spielen können.

Gemeint ist hier ein Freispiele Bonus ohne Einzahlung,

also die belohnte Registrierung. Kostenlose Online Casino Freispiele sind tatsächlich ohne Kosten möglich.

Um Freispiele in einem Casino im Internet zugeteilt zu bekommen, muss

man sich zuvor registrieren. Online Casino Freispiele oder anders ausgedrückt Free Spins, sind

in den besten Online Casinos ein Standard. Es ist daher absolut zu empfehlen, schon vor der Aktivierung der Freispiele einen genauen Blick auf

die Bedingungen und AGB des Casinos zu werfen. Die Merkur

Magie Automatenspiele können bei den meisten Anbietern auch mit Mobilgeräten gespielt werden.

Sie spielen stets direkt in dem Browser Ihrer Wahl und genießen dabei beste

graphische Auflösung. Erfahren Sie, wie Scatter-Symbole und weitere Besonderheiten funktionieren, und testen Sie, auf welchen Einsatzstufen Sie

das Spiel spielen wollen oder ob Sie die Gewinnlinien ändern können. Der Vorteil im Online Casino

ist, dass bei Online Slots und an den virtuellen Spieltischen die Limits sehr niedrig

sind, sodass Sie schon um geringe Summen spielen können.

[2025-12-06 04:40:41.617276]

URL

(Hellen)

Dianabol For Sale: Effectivity And Regulation

Tide Cleanser ? The Ultimate Cleaning Solution?

An in?depth look at Tide Cleanser’s composition, performance, and real?world

results

---

1. Introduction

When we think of laundry detergents, Tide is a

household name synonymous with reliable stain removal.

Yet over the last decade, Tide has expanded beyond washing powders into

a broader range of cleaning products. One of its most talked?about innovations is Tide Cleanser, marketed

as a "fast?acting, high?performance cleaning solution" that promises to tackle tough stains on a variety of surfaces?from clothing

and upholstery to kitchen counters and bathroom tiles.

But does Tide Cleanser live up to its bold claims? How does it

stack against competitors like OxiClean or Clorox’s bleach?based cleaners?

And what do independent lab tests say about its efficacy, safety, and environmental impact?

In this deep dive, we’ll examine Tide Cleanser from every angle: the chemistry behind its

formula, real?world performance on different materials, side?by?side lab

comparisons, user experiences, regulatory reviews, and eco?footprint assessments.

We aim to give you a clear, science?backed verdict so you can decide whether this product is worth adding to

your cleaning arsenal.

---

1. The Chemistry of Tide Cleanser

1.1 Core Ingredients and Their Roles

Ingredient Typical Function Example Concentration

Sodium carbonate (washing soda) Provides alkalinity;

reacts with organic acids to facilitate cleaning ~15?20?%

Surfactants (anionic, non?ionic) Lower surface tension; emulsify oils and dirt 5?8?%

Enzymes (protease, amylase, lipase) Break down protein, starch,

fat stains <0.1?%

Chelating agents (e.g., EDTA analogs) Sequester metal ions; prevent water hardness interference 0.5?2?%

Fragrances & colorants Enhance user experience; provide visual identity <0.05?%

The above formulation ensures compatibility with a wide range of detergents, maintaining efficacy across varying temperature regimes (cold to hot wash cycles). The inclusion of a mild surfactant (e.g., polysorbate) ensures the product remains soluble in all water types and does not precipitate or form insoluble complexes that could clog washing machines.

---

3. Manufacturing & Quality Control

Process Flow:

Raw Material Verification: Each batch of raw ingredients undergoes incoming inspection for purity, moisture content, and microbial load.

Mixing: High-shear mixers combine the powder constituents with the surfactant under controlled temperature to avoid clumping.

Drying & Granulation (Optional): If required, a spray-drying step ensures uniform particle size distribution.

Packaging: Automated filling lines dispense predetermined weights into tamper-proof plastic bags or sachets.

Quality Assurance Measures:

In-Process Sampling: At each stage, random samples are tested for moisture, particle size, and contaminant levels (e.g., heavy metals).

Final Product Testing: Each batch undergoes microbiological assays to confirm absence of pathogenic organisms.

Shelf-Life Studies: Accelerated aging tests determine optimal expiration dates under varying temperature and humidity conditions.

4. "What If" Scenario: Failure to Meet Quality Standards

A. Immediate Response Plan

Batch Recall

- Identify all affected lots via lot numbers, distribution records, and customer notifications.

- Issue a formal recall notice to distributors and retailers, detailing the reason for recall and safe disposal procedures.

Customer Notification

- Communicate transparently with end-users: explain the issue, potential risks, and steps taken to mitigate harm.

- Provide contact information for inquiries or reporting adverse events.

Internal Investigation

- Assemble a cross-functional team (Quality Assurance, Production, Supply Chain) to investigate root causes.

- Review all relevant records: raw material certificates, in-process controls, equipment logs, personnel training.

Corrective Actions

- Implement immediate fixes: recalibrate instruments, replace faulty components, rework or discard affected batches.

- Update SOPs and train staff on new procedures.

Regulatory Notification

- If required by local regulations (e.g., health authorities), file an incident report detailing the failure, actions taken, and expected impact on product safety.

Post-Implementation Review

- Monitor key performance indicators to confirm that corrective measures are effective.

- Schedule a follow-up audit or external review if necessary.

---

3. Detailed Analysis of Potential Causes and Mitigation Strategies

|

| Root Cause | Likely Impact | Immediate Action | Long?Term Prevention |

|---|------------|---------------|------------------|----------------------|

| 1 | Incorrect calibration of the scale ? zero not set, or drift in electronic balance. | Inaccurate mass reading; product may be under?filled (health risk) or over?filled (waste). | Re?calibrate using certified weights; verify zero and span accuracy. | Implement a scheduled recalibration protocol; maintain calibration log; use alarms for deviation thresholds. |

| 2 | Faulty load cell ? damaged, loose connection, or electromagnetic interference. | Erratic or flat line reading; potential failure to detect product presence. | Inspect wiring, replace load cell if faulty; shield against EMI. | Perform periodic electrical resistance checks; monitor for temperature-induced drift. |

| 3 | Mechanical obstruction or misalignment of weighing pan ? debris, improper mounting. | Product may not fully contact sensor; reading lower than actual weight. | Clean pan; verify proper alignment and surface integrity. | Conduct daily visual inspections; use calibration weights to confirm correct reading. |

| 4 | Software configuration error ? incorrect gain settings or unit conversion. | Misreported weight values (e.g., grams reported as kilograms). | Reconfigure software parameters; cross-check with known standards. | Implement sanity checks in firmware; log configuration changes for audit. |

| 5 | Power supply fluctuations or noise ? affecting sensor electronics. | Erratic readings, increased variance. | Use stable power supplies; filter noise; ensure proper grounding. | Monitor voltage levels; include error detection and auto-reset routines. |

---

3. Design Review Meeting Minutes

3.1 Attendees

Project Lead (PL) ? Overall project oversight.

Mechanical Engineer (ME) ? Responsible for chassis design, material selection, and structural integrity.

Electrical Engineer (EE) ? Oversees sensor integration, power management, and electronics.

Software Engineer (SE) ? Handles firmware, data acquisition, and system control.

Quality Assurance Lead (QA) ? Ensures compliance with standards and testing protocols.

3.2 Agenda

Review of mechanical design status and upcoming milestones.

Discussion on sensor selection and integration strategy.

Evaluation of material choices for chassis and structural components.

Identification of potential risks and mitigation plans.

3.2.1 Mechanical Design Status

EE presented the latest CAD models, highlighting the updated chassis dimensions to accommodate the selected sensors. The design includes modular mounting brackets allowing future sensor replacements without extensive rework.

QA raised concerns about the tolerance stack-up in the assembly process. Suggested incorporating a more robust jigging system during machining to reduce dimensional variation.

3.2.2 Sensor Selection

EE confirmed that the chosen laser rangefinder (Model X) and ultrasonic sensor (Model Y) meet the required accuracy specifications: ±0.5?mm for short-range measurements (<1?m). The sensors provide digital outputs with minimal processing overhead.

EE also identified potential electromagnetic interference (EMI) issues due to proximity of power supplies. Proposed adding shielded cabling and placing dedicated EMI filters on sensor inputs.

3.2.3 Integration Challenges

EE highlighted that the high-frequency data stream (~1?kHz) from sensors will increase CPU load. Suggested implementing a dedicated interrupt-driven data acquisition routine in firmware to buffer samples before passing them to the main control loop.

EE recommended synchronizing sensor readings with the plant’s internal clock using NTP or an external timestamp source to maintain temporal coherence across all data sources.

3. Decision Matrix

Criterion Weight (1?5) Option A: Sensor?only Monitoring Option B: Sensor + Data Integration

Data Accuracy 5 Medium (no cross?check) High (cross?validated with plant data)

Response Time 4 Fast (direct sensor output) Slightly slower (additional processing)

System Complexity 3 Low Moderate to high

Implementation Cost 2 Low (existing sensors) Medium (additional integration effort)

Scalability 4 Good (add more sensors) Depends on data pipeline capacity

Reliability / Redundancy 3 Limited (single sensor per node) Improved via cross-checks with other nodes

Assigning weights to each criterion based on organizational priorities, we can compute a weighted score for both strategies. If the decision-maker values simplicity and cost highly (weights favoring low implementation cost and low complexity), the simple strategy may prevail. Conversely, if reliability and redundancy are paramount (higher weight on redundancy and cross-validation), the integrated strategy may be justified despite higher overhead.

---

5. Decision-Making Flowchart

Below is a textual representation of a decision tree that can guide managers:

START

|

|-- Is the network critical for mission success?

| |-- No --> Opt for simple monitoring (low cost, low complexity).

| |-- Yes --> Proceed.

|

|-- What is the acceptable level of risk?

| |-- High tolerance (e.g., non-critical data) --> Simple strategy.

| |-- Low tolerance (mission-critical data) --> Integrated

strategy.

|

|-- Are resources available to deploy and maintain local monitoring agents?

| |-- No --> Simple strategy (use existing network monitoring).

| |-- Yes --> Proceed.

|

|-- Can the system tolerate delayed detection of anomalies (e.g.,

seconds to minutes)?

| |-- Yes --> Simple strategy may suffice with periodic sampling.

| |-- No (needs real-time detection) --> Integrated strategy required.

|

|-- Decision: Choose strategy that balances detection granularity, resource constraints,

and risk tolerance.

This flowchart can be refined or automated within the system

configuration process.

---

4. Deployment Blueprint

Below is a high?level deployment plan outlining infrastructure components, data flows, and

security measures for each layer of the anomaly detection architecture.

4.1 Infrastructure Overview

Layer Component Purpose Deployment Notes

Physical Data Acquisition Sensors / Devices Capture raw sensor streams (e.g., accelerometers) Place in proximity to physical system; ensure proper shielding and grounding

Data Ingestion Edge Collectors (Kafka Producers) Buffer incoming data, perform minimal preprocessing Run on local servers or embedded devices; use

TLS for secure transmission

Streaming Layer Kafka Cluster + Spark Structured Streaming Real-time data

pipeline; compute streaming statistics Deploy in a high-availability mode; partition topics by sensor

type

Batch Processing Spark Batch Jobs Historical aggregation, model training Schedule nightly jobs on cluster; store outputs in HDFS or S3

Feature Store Cassandra / DynamoDB Persist features for online inference Ensure low-latency reads;

implement TTLs if needed

Inference Service TensorFlow Serving + Flask API Serve predictions with minimal

latency Deploy behind load balancer; use GPU instances if model is heavy

Monitoring & Logging Prometheus, Grafana, ELK stack Track performance metrics

and logs Set alerts on prediction drift or

service errors

---

7. Summary

By rigorously defining the data sources, sampling strategy, feature engineering pipeline, and modeling workflow?including both classical and deep

learning approaches?we establish a robust foundation for deploying accurate, low?latency predictive models in an industrial setting.

The modular architecture ensures scalability, maintainability, and compliance with stringent real?time constraints

typical of high?speed production environments.

Continuous monitoring and periodic re?training will sustain model

relevance as process dynamics evolve over time. This

framework can be adapted to other manufacturing contexts requiring similar data?driven decision support.

Tide Cleanser ? The Ultimate Cleaning Solution?

An in?depth look at Tide Cleanser’s composition, performance, and real?world

results

---

1. Introduction

When we think of laundry detergents, Tide is a

household name synonymous with reliable stain removal.

Yet over the last decade, Tide has expanded beyond washing powders into

a broader range of cleaning products. One of its most talked?about innovations is Tide Cleanser, marketed

as a "fast?acting, high?performance cleaning solution" that promises to tackle tough stains on a variety of surfaces?from clothing

and upholstery to kitchen counters and bathroom tiles.

But does Tide Cleanser live up to its bold claims? How does it

stack against competitors like OxiClean or Clorox’s bleach?based cleaners?

And what do independent lab tests say about its efficacy, safety, and environmental impact?

In this deep dive, we’ll examine Tide Cleanser from every angle: the chemistry behind its

formula, real?world performance on different materials, side?by?side lab

comparisons, user experiences, regulatory reviews, and eco?footprint assessments.

We aim to give you a clear, science?backed verdict so you can decide whether this product is worth adding to

your cleaning arsenal.

---

1. The Chemistry of Tide Cleanser

1.1 Core Ingredients and Their Roles

Ingredient Typical Function Example Concentration

Sodium carbonate (washing soda) Provides alkalinity;

reacts with organic acids to facilitate cleaning ~15?20?%

Surfactants (anionic, non?ionic) Lower surface tension; emulsify oils and dirt 5?8?%

Enzymes (protease, amylase, lipase) Break down protein, starch,

fat stains <0.1?%

Chelating agents (e.g., EDTA analogs) Sequester metal ions; prevent water hardness interference 0.5?2?%

Fragrances & colorants Enhance user experience; provide visual identity <0.05?%

The above formulation ensures compatibility with a wide range of detergents, maintaining efficacy across varying temperature regimes (cold to hot wash cycles). The inclusion of a mild surfactant (e.g., polysorbate) ensures the product remains soluble in all water types and does not precipitate or form insoluble complexes that could clog washing machines.

---

3. Manufacturing & Quality Control

Process Flow:

Raw Material Verification: Each batch of raw ingredients undergoes incoming inspection for purity, moisture content, and microbial load.

Mixing: High-shear mixers combine the powder constituents with the surfactant under controlled temperature to avoid clumping.

Drying & Granulation (Optional): If required, a spray-drying step ensures uniform particle size distribution.

Packaging: Automated filling lines dispense predetermined weights into tamper-proof plastic bags or sachets.

Quality Assurance Measures:

In-Process Sampling: At each stage, random samples are tested for moisture, particle size, and contaminant levels (e.g., heavy metals).

Final Product Testing: Each batch undergoes microbiological assays to confirm absence of pathogenic organisms.

Shelf-Life Studies: Accelerated aging tests determine optimal expiration dates under varying temperature and humidity conditions.

4. "What If" Scenario: Failure to Meet Quality Standards

A. Immediate Response Plan

Batch Recall

- Identify all affected lots via lot numbers, distribution records, and customer notifications.

- Issue a formal recall notice to distributors and retailers, detailing the reason for recall and safe disposal procedures.

Customer Notification

- Communicate transparently with end-users: explain the issue, potential risks, and steps taken to mitigate harm.

- Provide contact information for inquiries or reporting adverse events.

Internal Investigation

- Assemble a cross-functional team (Quality Assurance, Production, Supply Chain) to investigate root causes.

- Review all relevant records: raw material certificates, in-process controls, equipment logs, personnel training.

Corrective Actions

- Implement immediate fixes: recalibrate instruments, replace faulty components, rework or discard affected batches.

- Update SOPs and train staff on new procedures.

Regulatory Notification

- If required by local regulations (e.g., health authorities), file an incident report detailing the failure, actions taken, and expected impact on product safety.

Post-Implementation Review

- Monitor key performance indicators to confirm that corrective measures are effective.

- Schedule a follow-up audit or external review if necessary.

---

3. Detailed Analysis of Potential Causes and Mitigation Strategies

|

| Root Cause | Likely Impact | Immediate Action | Long?Term Prevention |

|---|------------|---------------|------------------|----------------------|

| 1 | Incorrect calibration of the scale ? zero not set, or drift in electronic balance. | Inaccurate mass reading; product may be under?filled (health risk) or over?filled (waste). | Re?calibrate using certified weights; verify zero and span accuracy. | Implement a scheduled recalibration protocol; maintain calibration log; use alarms for deviation thresholds. |

| 2 | Faulty load cell ? damaged, loose connection, or electromagnetic interference. | Erratic or flat line reading; potential failure to detect product presence. | Inspect wiring, replace load cell if faulty; shield against EMI. | Perform periodic electrical resistance checks; monitor for temperature-induced drift. |

| 3 | Mechanical obstruction or misalignment of weighing pan ? debris, improper mounting. | Product may not fully contact sensor; reading lower than actual weight. | Clean pan; verify proper alignment and surface integrity. | Conduct daily visual inspections; use calibration weights to confirm correct reading. |

| 4 | Software configuration error ? incorrect gain settings or unit conversion. | Misreported weight values (e.g., grams reported as kilograms). | Reconfigure software parameters; cross-check with known standards. | Implement sanity checks in firmware; log configuration changes for audit. |

| 5 | Power supply fluctuations or noise ? affecting sensor electronics. | Erratic readings, increased variance. | Use stable power supplies; filter noise; ensure proper grounding. | Monitor voltage levels; include error detection and auto-reset routines. |

---

3. Design Review Meeting Minutes

3.1 Attendees

Project Lead (PL) ? Overall project oversight.

Mechanical Engineer (ME) ? Responsible for chassis design, material selection, and structural integrity.

Electrical Engineer (EE) ? Oversees sensor integration, power management, and electronics.

Software Engineer (SE) ? Handles firmware, data acquisition, and system control.

Quality Assurance Lead (QA) ? Ensures compliance with standards and testing protocols.

3.2 Agenda

Review of mechanical design status and upcoming milestones.

Discussion on sensor selection and integration strategy.

Evaluation of material choices for chassis and structural components.

Identification of potential risks and mitigation plans.

3.2.1 Mechanical Design Status

EE presented the latest CAD models, highlighting the updated chassis dimensions to accommodate the selected sensors. The design includes modular mounting brackets allowing future sensor replacements without extensive rework.

QA raised concerns about the tolerance stack-up in the assembly process. Suggested incorporating a more robust jigging system during machining to reduce dimensional variation.

3.2.2 Sensor Selection

EE confirmed that the chosen laser rangefinder (Model X) and ultrasonic sensor (Model Y) meet the required accuracy specifications: ±0.5?mm for short-range measurements (<1?m). The sensors provide digital outputs with minimal processing overhead.

EE also identified potential electromagnetic interference (EMI) issues due to proximity of power supplies. Proposed adding shielded cabling and placing dedicated EMI filters on sensor inputs.

3.2.3 Integration Challenges

EE highlighted that the high-frequency data stream (~1?kHz) from sensors will increase CPU load. Suggested implementing a dedicated interrupt-driven data acquisition routine in firmware to buffer samples before passing them to the main control loop.

EE recommended synchronizing sensor readings with the plant’s internal clock using NTP or an external timestamp source to maintain temporal coherence across all data sources.

3. Decision Matrix

Criterion Weight (1?5) Option A: Sensor?only Monitoring Option B: Sensor + Data Integration

Data Accuracy 5 Medium (no cross?check) High (cross?validated with plant data)

Response Time 4 Fast (direct sensor output) Slightly slower (additional processing)

System Complexity 3 Low Moderate to high

Implementation Cost 2 Low (existing sensors) Medium (additional integration effort)

Scalability 4 Good (add more sensors) Depends on data pipeline capacity

Reliability / Redundancy 3 Limited (single sensor per node) Improved via cross-checks with other nodes

Assigning weights to each criterion based on organizational priorities, we can compute a weighted score for both strategies. If the decision-maker values simplicity and cost highly (weights favoring low implementation cost and low complexity), the simple strategy may prevail. Conversely, if reliability and redundancy are paramount (higher weight on redundancy and cross-validation), the integrated strategy may be justified despite higher overhead.

---

5. Decision-Making Flowchart

Below is a textual representation of a decision tree that can guide managers:

START

|

|-- Is the network critical for mission success?

| |-- No --> Opt for simple monitoring (low cost, low complexity).

| |-- Yes --> Proceed.

|

|-- What is the acceptable level of risk?

| |-- High tolerance (e.g., non-critical data) --> Simple strategy.

| |-- Low tolerance (mission-critical data) --> Integrated

strategy.

|

|-- Are resources available to deploy and maintain local monitoring agents?

| |-- No --> Simple strategy (use existing network monitoring).

| |-- Yes --> Proceed.

|

|-- Can the system tolerate delayed detection of anomalies (e.g.,

seconds to minutes)?

| |-- Yes --> Simple strategy may suffice with periodic sampling.

| |-- No (needs real-time detection) --> Integrated strategy required.

|

|-- Decision: Choose strategy that balances detection granularity, resource constraints,

and risk tolerance.

This flowchart can be refined or automated within the system

configuration process.

---

4. Deployment Blueprint

Below is a high?level deployment plan outlining infrastructure components, data flows, and

security measures for each layer of the anomaly detection architecture.

4.1 Infrastructure Overview

Layer Component Purpose Deployment Notes

Physical Data Acquisition Sensors / Devices Capture raw sensor streams (e.g., accelerometers) Place in proximity to physical system; ensure proper shielding and grounding

Data Ingestion Edge Collectors (Kafka Producers) Buffer incoming data, perform minimal preprocessing Run on local servers or embedded devices; use

TLS for secure transmission

Streaming Layer Kafka Cluster + Spark Structured Streaming Real-time data

pipeline; compute streaming statistics Deploy in a high-availability mode; partition topics by sensor

type

Batch Processing Spark Batch Jobs Historical aggregation, model training Schedule nightly jobs on cluster; store outputs in HDFS or S3

Feature Store Cassandra / DynamoDB Persist features for online inference Ensure low-latency reads;

implement TTLs if needed

Inference Service TensorFlow Serving + Flask API Serve predictions with minimal

latency Deploy behind load balancer; use GPU instances if model is heavy

Monitoring & Logging Prometheus, Grafana, ELK stack Track performance metrics

and logs Set alerts on prediction drift or

service errors

---

7. Summary

By rigorously defining the data sources, sampling strategy, feature engineering pipeline, and modeling workflow?including both classical and deep

learning approaches?we establish a robust foundation for deploying accurate, low?latency predictive models in an industrial setting.

The modular architecture ensures scalability, maintainability, and compliance with stringent real?time constraints

typical of high?speed production environments.

Continuous monitoring and periodic re?training will sustain model

relevance as process dynamics evolve over time. This

framework can be adapted to other manufacturing contexts requiring similar data?driven decision support.

[2025-09-27 01:02:46.033227]

URL